About Us

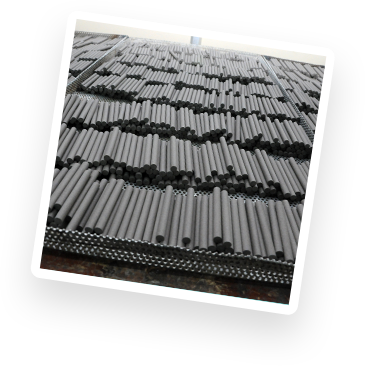

Vapo Minerals Pvt. Ltd. is one of the premier wicks manufacturing companies in India, headquartered in Pondichery. From it's inception in 2004 with a single production unit Vapo has now been augmented to 5 state-of-the-art units in accordance with the international standards. Vapo is one of the largest wick manufacturers with ISO 9001 - 2015 certifications, and has established a reputation in supplying superior quality wicks at competitive prices.

Vapo has earned trust, numerous accolades and has become one of the favorites among the repellent manufacturers. All credits go to our highly qualified and dedicated staff who are the reason for the higher productivity and superior quality of the products.

While completing a decade of excellence, Vapo Minerals already made its global presence in Bangladesh, Nepal, Srilanka and Brazil with a vision of increasing the presence from 3 destinations to 30 destinations across the globe.

Thus stepping up towards global eminence.

Vision

To become a premier global supplier by providing exceptional value to our customer with an intense focus on quality, consistency and support.

Mission

To provide excellent products, manufacturing services and establish a mutually beneficial, long-term association.

To increase exposure to global market competitiveness and adopt a culture of continual improvement and dedication.

To share the responsibilities to achieve an ultimate goal: Zero defects in everything we do.

Environment Policy

Vapo's GUTS is an evident crusade to minimize the environmental impact of our operations. We aggressively pursue the prevention of pollution, reduction of wastage, energy conservation and prevention of natural resources.

Vapo's GUTS

- Guard resources

- Usher ideas

- Train Employees

- Society First

Quality First

With extremely qualified personnel we also have the facilities to maintain quality at all levels.

- The company have very stringent quality control systems. The incoming, in-process and final inspections are carried out based on the pre-planned quality plan.

- The critical process are controlled through statistical quality control charts like X bar R chart and run charts.

- Quality records are maintained at all stages to ensure the inspection data are recorded for future reference.

- Quality control awareness and on job trainings are conducted and records are maintained.

- Rejections analysis are carried out and discussed in CPAG meeting for quality improvement monthly once.

- Daily prayer meetings are conducted for reviewing the previous day quality performance and achievement on daily basis.

- Visual displays are used for quick understanding of product status.

- Batch systems are followed for identification and traceability.

- Performance testing of own wicks and recorded.